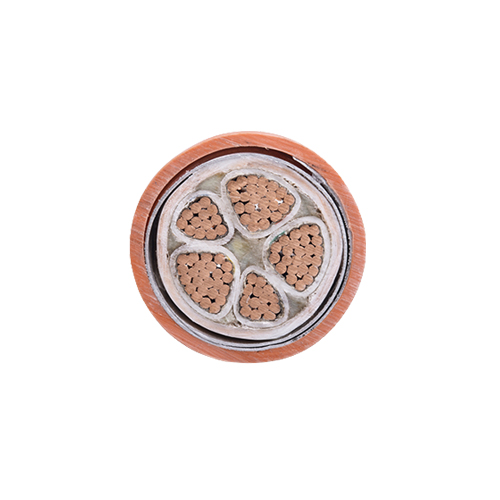

Mineral Insulated Metal Sheathed MIMS Cable

- SIMSHENG

- China

- 15-20 days delivery after receipt of payment

- 5000000meters/day

At present, China's common 3 types of fireproof cable

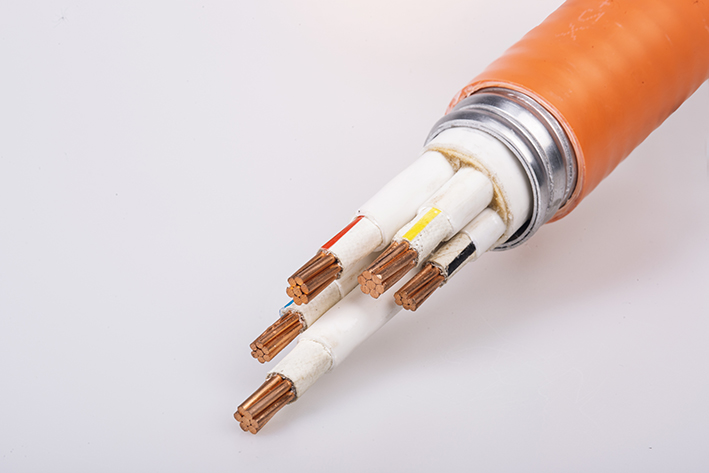

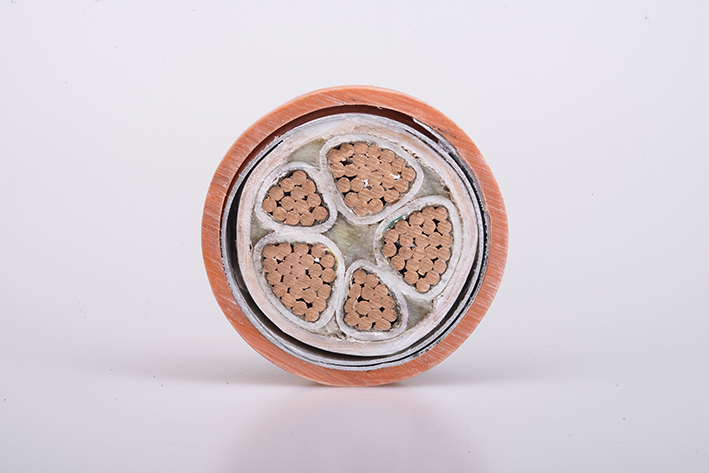

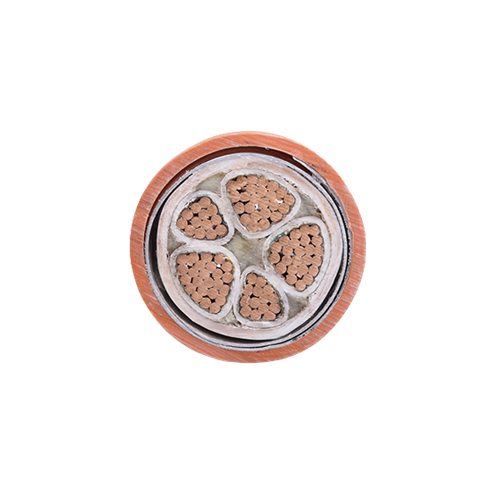

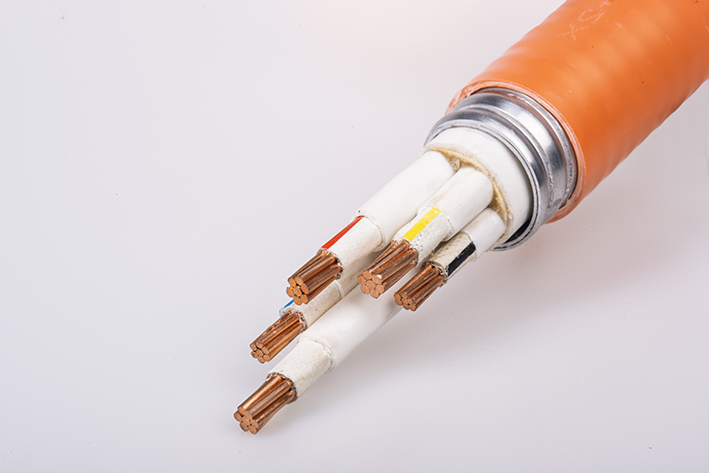

Copper core copper sheathed magnesium oxide insulated cable: it is composed of solid copper rod, magnesium oxide insulation and seamless copper pipe sheath. (without outer sheath BTTZ, BTTQ, with outer sheath BTTVZ, BTTVQ, WD-BTTYZ)

Flexible inorganic mica with mineral insulation cable: it is composed of copper stranded wire, fluorine mica with insulation and copper belt with longitudinal wrapped continuous welding sheath. (without outer sheath YTTW, RTTZ, with outer sheath YTTWV, WD-YTTWY, RTTZV, WR-RTTZY, BTTW, BTTRZ).

Flexible isolation type aluminum sheath mineral insulation cable (NG-A, BTLY) : it is composed of copper strand, gold mica tape insulation, seamless aluminum tube sheath, oxygen insulation layer filling, isolation refractory layer, low smoke halogen-free sheath.

Product Description

1. Fire resistance

Copper and mineral insulation of the two materials used in mineral insulation cables are inorganic materials. The cable does not burn or help fuel, and can continue to operate under conditions near the flame. The copper sheath was melted at 1083 °C.

2. High operating temperature

Mineral insulated cables can withstand continuous operating temperatures up to 250°C and, in an emergency, the cables can continue for a short time near the melting point of the copper sheath.

3. Durable

Inorganic materials used in mineral insulated cables can guarantee cable stability, durability and fire resistance.

4. Explosion-proof

Highly compacted insulation in mineral insulated cables that prevents steam, gas and flames from passing between parts of the equipment connected to the cable

5. Small outer diameter

Mineral insulated cables have a smaller diameter than other cables with the same rated current.

6. Waterproof

If mineral insulation is completely submerged in water to assist the metal sheath, mineral insulation may be continued

7. High mechanical strength

Mineral insulated cables are strong and durable to withstand severe mechanical damage without compromising their electrical properties.

8. Large load flow

For the same section, mineral insulated cables transmit higher current than other types of cables. At the same time, mineral insulated cables can also withstand considerable overload

9. Short-circuit fault fixed value is high

At the same temperature, the short circuit fault fixed value of mineral insulated cables is significantly higher than the other cables.

10. Copper sheath can be used as a grounding wire

For mineral insulated cables, independent grounding wires are not required because the copper sheath used in this cable has acted as grounding wires to provide good low grounding resistance. In terms of ground leather loop (ESR) wiring, the outer copper sheath can be used as a ground and neutral conductor in the MEN multi-ground neutral) system.

11. High corrosion resistance

The copper sheath of mineral insulated cables has high corrosion resistance and for most devices does not require additional protection. Mineral insulated cables shall be protected with plastic sheath where copper sheath are susceptible to chemical corrosion or severe industrial pollution.

Application: Mineral insulated cables have been widely used in high-rise buildings, petrochemical industries, airports, tunnels, ships, offshore oil platforms, aerospace, iron and steel metallurgy, shopping centers, parking lots and other places.