What is the reason for the oxidation of wires and cables?

Some consumers have found that the copper core of the conductor will turn black after a period of time if the wires and cables they bought are not properly stored. At this time, they think they have bought cable products of poor quality. In fact, most wires and cables use copper core as conductor, and copper is a transition metal. It is widely used as a conductor because of its good thermal conductivity and electrical conductivity. However, in humid air, the surface of copper will react chemically with oxygen to form Cu2(OH)2CO3, which we often call verdigris. Usually, copper oxidation of wires and cables is manifested as blackening of the surface, which is a phenomenon of copper conductor surface oxidation that troubles many cable companies and users. However, in addition to the production process, there are various other factors that can cause wires and cables to turn black during use. Next, Foshan Yuejiaxin Company will share with you some of the most easily overlooked reasons for oxidation of wires and cables.

1. Improper handling of cable joints

If the cable joints are not properly sealed, it is easy to cause air to invade the copper conductor and cause blackening. For the packaging of cable heads, most companies or electricians use insulating tape to seal them directly. In fact, the insulating tape is not waterproof and there is a layer of glue on it, which will make the cable black over time.

2. Insulation and moisture

This situation is also very common in our daily life, and generally occurs at the cable joints in direct burial or drainage pipes. If the cable joints are not made up to standard and are made under humid climate conditions, water will enter the joints or water vapor will mix into the joints, and the cable will turn black over time. This phenomenon is more common in hot summers, because the humidity in the air is relatively high in summer, and the temperature is relatively high in summer. The high temperature and high humidity environment will accelerate the oxidation reaction of copper conductors.

3. Construction and installation

Some users do not standardize the construction when laying and installing cables, which is easy to cause mechanical damage; civil construction on direct buried cables is also very easy to damage the running cables. If the local damage of the copper conductor of the cable is damp underground for a long time or the exposed surface will cause oxidation and blackening. In addition to the above reasons for the blackening and discoloration of the cable port, the easy blackening of copper also shows a more important problem, that is, the poor quality of copper, which accounts for a large part of the cable cost. If the copper quality is not good, it means that there are problems in other aspects. After taking protective measures, if the copper is still oxidized and blackened, such cables should be replaced in time.

The above are some of the more common reasons that may cause oxidation of wires and cables in our daily lives. Foshan Yuejiaxin Wire and Cable Co., Ltd. is a professional manufacturer of wires and cables with more than 20 years of production experience. If you want to know more about wire and cable knowledge, please continue to pay attention to our company's website.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

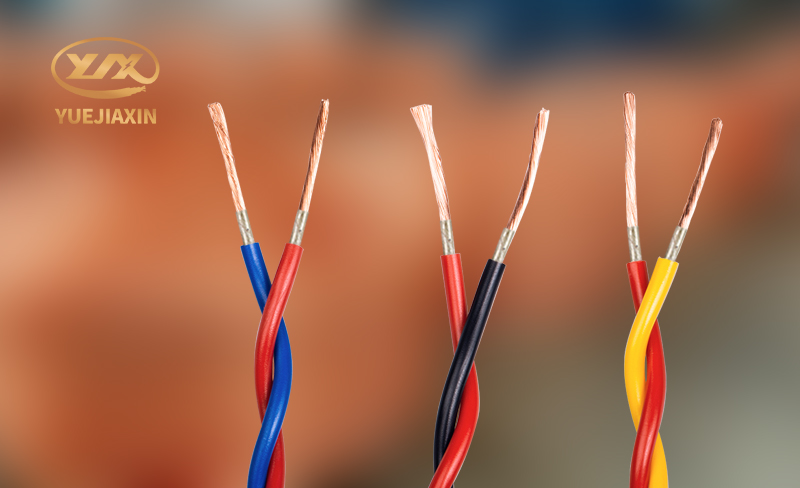

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

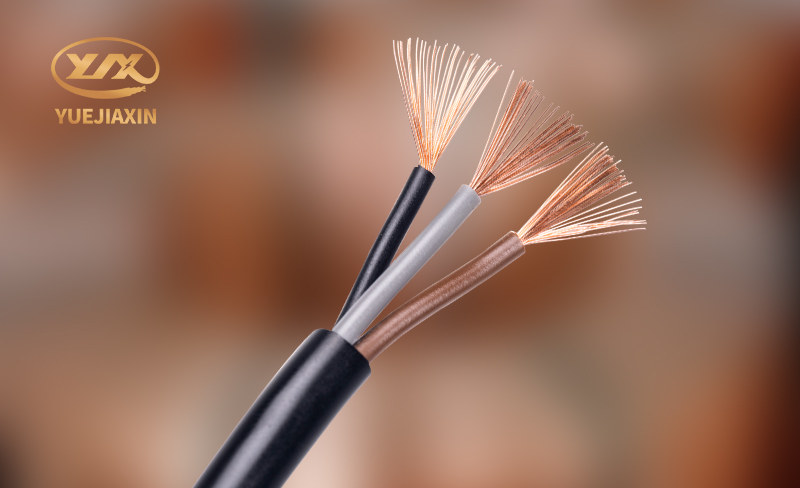

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable