Today I will introduce you to aluminum core cable

In recent years, aluminum core cables have become more and more popular among consumers and are a good choice for many consumers. Next, the wire and cable manufacturer will take you to learn about aluminum core cables.

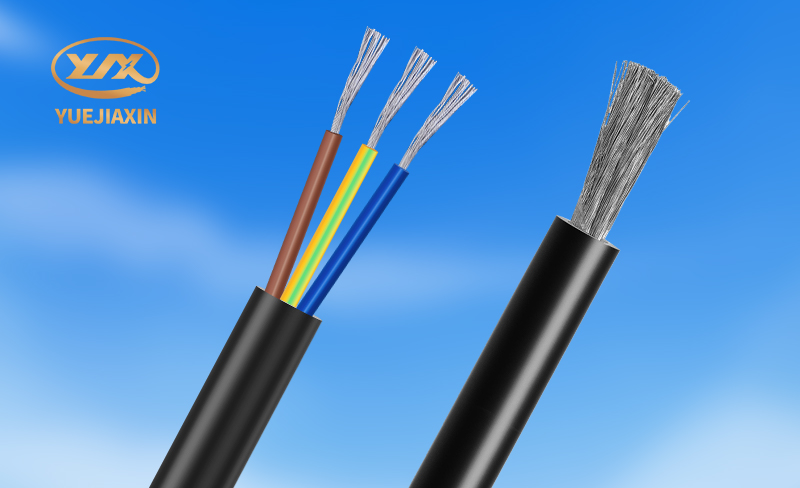

First of all, the material used for aluminum core cables is pure aluminum or aluminum alloy. Aluminum core cables usually refer to copper-clad aluminum cables, that is, aluminum core wires are used instead of copper as the main body of wires and cables, and the outer layer is wrapped with a certain number of copper layers. This design combines the advantages of aluminum and copper, so that the cable has both the lightweight and cost advantages of aluminum and maintains the conductive properties of copper.

Aluminum core cables are widely used in many fields, and their important role is mainly reflected in the following aspects: In terms of power transmission, aluminum core cables have good electrical conductivity and can effectively transmit power signals. It is widely used in power transmission occasions, including urban power supply networks, industrial power consumption, and power distribution inside buildings. Especially in long-distance power transmission lines, aluminum core cables can reduce the overall cost of the line and help reduce power loss due to their light weight and good electrical conductivity. Compared with traditional copper core cables, aluminum core cables have the advantages of light weight and low cost. This makes it easier to achieve the goals of lightweight and energy saving and emission reduction in power system design. The weight of aluminum cable is about 40% of that of copper core wire, so the cost will be reduced accordingly during construction and transportation.

Aluminum cables have high antioxidant and corrosion resistance, because aluminum reacts quickly with oxygen to form an oxide film, which can avoid deep oxidation, so aluminum core cables have good antioxidant and corrosion resistance. This makes aluminum core cables an indispensable material for high-current, large-section, and large-span overhead line transmission networks. Aluminum core cables are more cost-effective, because the price of copper is much higher than that of aluminum, and aluminum core cables have significant cost advantages. This makes aluminum core cables an ideal choice for low-demand engineering construction or temporary power supply. In addition, aluminum core cables also have excellent thermal insulation properties, which makes them suitable for use in various environments, especially high temperature and high pressure environments. In terms of maintenance, aluminum core cables are relatively simple and do not require frequent maintenance, which helps to reduce maintenance costs.

In summary, aluminum core cables, with their unique materials and characteristics, play an important role in power transmission, lightweight design, anti-oxidation and corrosion resistance, high cost performance, excellent thermal insulation performance and simple maintenance. Whether in urban power supply grids, industrial power, power distribution inside buildings, or long-distance power transmission lines, aluminum core cables play an indispensable role.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable