Can fire-resistant cables replace flame-retardant cables?

First of all, let's understand the difference between fire-resistant cables and flame-retardant cables. Flame-retardant wires, in simple terms, can effectively curb the spread of fire when encountering a fire. And once the source of fire disappears, it can extinguish itself. That is, when a fire accidentally breaks out, this flame-retardant cable can limit the scope of combustion to a local area, prevent the fire from spreading outward, thereby protecting other types of equipment and minimizing losses.

The reason why flame-retardant cables have this characteristic is because of the special materials used. The higher the oxygen index of the material used, the better its flame retardant performance. However, as the oxygen index continues to increase, some other properties will inevitably be sacrificed. For example, the physical properties and process properties of the material will decline, it will become difficult during operation, and the material cost will increase accordingly. The materials used in flame-retardant wires and cables can be mainly divided into halogen-containing flame-retardant materials and halogen-free flame-retardant materials.

After adding halogen-containing halides and metal oxides to the sheath material of flame-retardant wires and cables, these substances will decompose and release hydrogen halides during the combustion and heating process. Hydrogen halides can capture active free radicals, HO roots, which can delay or extinguish the combustion of materials and achieve the purpose of flame retardancy.

Although flame-retardant cables have many advantages suitable for chemical companies, such as low halogen, low smoke flame retardant, etc., in general, we will use fire-resistant cables to replace flame-retardant cables, but conversely, flame-retardant cables cannot replace fire-retardant cables. The differences between them are mainly reflected in the following aspects:

First, the difference in principle. There are differences in the principles of fire-resistant cables and flame-retardant wires. The flame-retardant principle of halogen-containing cables relies on halogens to exert flame-retardant effects, while the flame-retardant principle of halogen-free cables is to extinguish flames by precipitating water to lower the temperature. Fire-resistant cables rely on the fire-resistant and heat-resistant properties of mica materials in the fire-resistant layer to ensure that the cables can still work normally when a fire occurs.

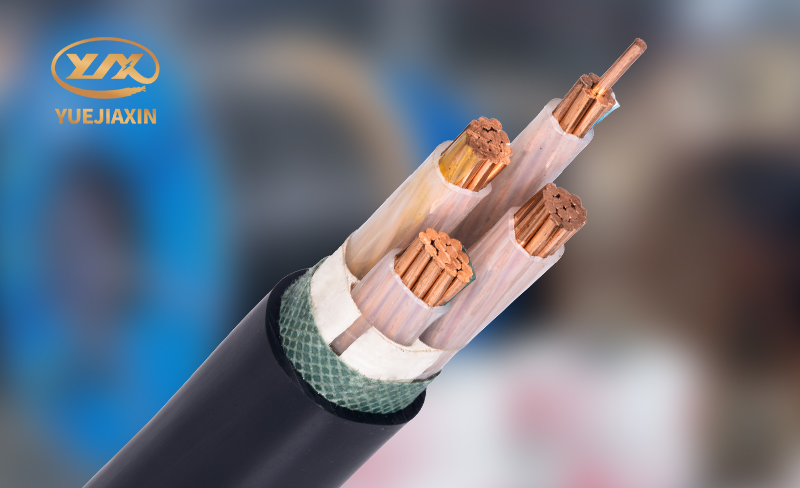

Second, the difference in structure and materials. Flame-retardant cables and fire-resistant cables are also different in structure and materials. The basic structure of flame-retardant cables includes: the insulation layer is made of flame-retardant materials; the sheath and outer sheath are made of flame-retardant materials; the wrapping tape and filling are made of flame-retardant materials.

Fire-resistant cables usually have an additional fire-resistant layer between the conductor and the insulation layer. Theoretically, it seems possible to add a fire-resistant layer to the structure of a flame-retardant cable to form a cable that is both flame-retardant and fire-resistant, but in fact this is not necessary. The fire-resistant layer of a fire-resistant cable is generally made of multiple layers of mica tape wrapped directly on the conductor. This structure enables it to withstand long-term burning, and even if the polymer is burned where the flame is applied, it can still ensure the normal operation of the line.

In addition, we also need to realize that in actual application scenarios, whether it is flame-retardant cable or fire-resistant cable, it needs to be selected according to the specific environment and needs. For example, in some places with high requirements for smoke and toxic gas emissions, halogen-free flame-retardant cable may be a better choice; and in places with extremely high requirements for cable fire resistance, such as some important power facilities or fire-fighting facilities, fire-resistant cables are indispensable. This requires us to comprehensively consider many factors when selecting cables, including but not limited to safety, economy, environmental adaptability, etc., to ensure that the selected cables can meet the use requirements in various complex situations and ensure the safety of equipment and personnel.