How to choose between BV and BVR?

How should we choose from the various wires on the market? Today, the wire and cable manufacturer will talk about the two most common wires in home decoration - BV wire and BVR wire, so that we can understand the difference between them at one time and make the right choice easily!

| Compare Projects | BV wire | BVR wire |

| structure | Single-strand hard copper wire | Multi-strand soft copper wire |

| Appearance | Harder, not easy to bend | Soft, easy to bend |

| Electrical conductivity | Slightly better conductivity for the same cross-sectional area | Slightly inferior conductivity |

| Fatigue resistance | Poor, easy to break after repeated bending | Good, suitable for frequent bending scenes |

| Application Scenario | Fixed wiring, such as hidden wires in walls and ceilings | Occasions where bending is required, such as wiring inside distribution boxes |

Structurally, the BV line is made up of a single strand of hard copper wire, which makes it look very "tough" and difficult to bend. The BVR line is made up of multiple strands of fine copper wires, which are soft and can easily adapt to various bending scenarios. It's like it's difficult to bend a chopstick, but it's relatively easy to bend a bunch of chopsticks tied together. These two different structures also determine their differences in performance and usage scenarios.

In terms of flexibility, BVR wire is definitely the undisputed king. Its soft characteristics make it easy to bend frequently. BV wire is more difficult to bend, and it is easy to break after repeated bending, so it is more suitable for fixed wiring. Since BVR wire is made of multiple strands of copper wire, there are gaps between each copper wire, which is more susceptible to oxidation and corrosion than BV wire. Especially in some humid and corrosive environments, the service life of BVR wire will be greatly affected. The structure of single-strand copper wire of BV wire is relatively more corrosion-resistant and more stable. Generally speaking, the price of BVR wire is slightly higher than that of BV wire. This is mainly because the manufacturing process of BVR wire is relatively complicated, and multiple strands of fine copper wire need to be twisted together, so the cost naturally goes up. BV wire has a simple structure, a relatively easy production process, and a more affordable price. Therefore, if your budget is limited, BV wire is a good choice. But if the budget is sufficient and there are higher requirements for the performance of the wire, BVR wire is also worth considering.

When choosing wires, you must base it on your actual needs and don't blindly follow the trend. At the same time, you should also pay attention to choosing regular brands and reliable quality products to ensure the safety of household electricity. Since its establishment in 1999, Foshan Yuejiaxin Wire and Cable Co., Ltd. has been focusing on the production of wires and cables with high quality and reliable quality.

- PVC-Insulated Cable

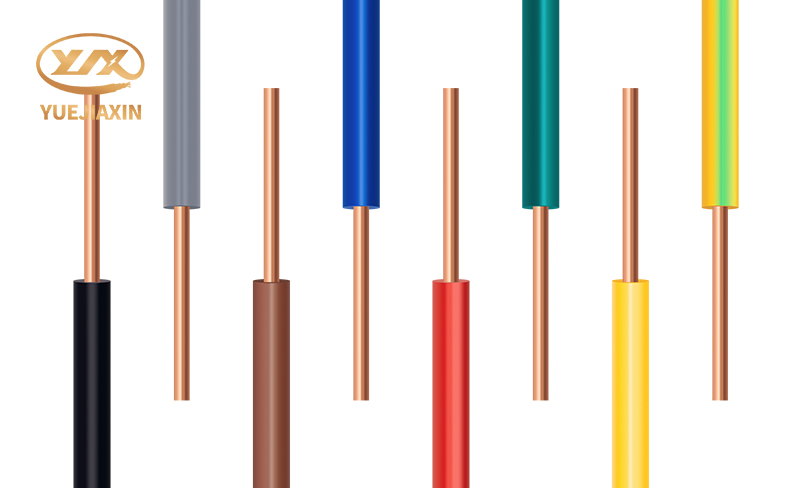

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

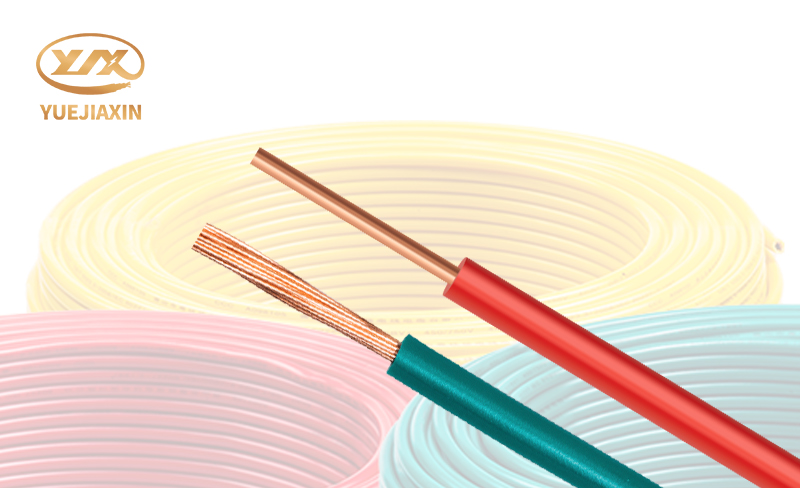

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable