Wire and cable manufacturers teach you how to choose control cables

Control cables play a vital role in the fields of industrial automation, building electrical and energy transmission. Choosing the right control cable is not only related to the stable operation of the system, but also directly affects safety and efficiency. Wire and cable manufacturers will provide you with a detailed guide to control cable selection through this article to help you make a wise choice.

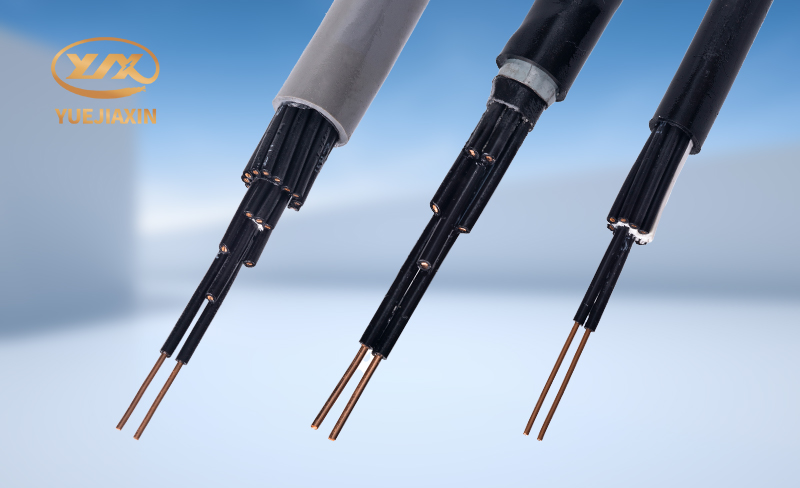

First, we understand the basic concept of control cable. Control cable is mainly used to transmit electrical signals and instructions in control systems. Its characteristics are small cross-sectional area, large number of cores, and bending resistance. Common control cable models include KVV, KYJV, KVVP, etc. Each model has its specific application scenarios and performance requirements. Then, we need to determine the use environment of the control cable. For example, we can choose the right cable according to the temperature of the working environment to ensure that the cable can still work normally under extreme temperatures. Humidity conditions should also be considered. For example, in high humidity or underwater environments, cables with good waterproof performance should be selected. In particular, if there are chemical corrosive substances in the environment, corrosion-resistant cables should be selected. It is also necessary to consider whether the cable will be subjected to mechanical stress such as stretching, compression or torsion to select cables of corresponding strength. In addition, the electrical performance of the control cable needs to be considered. According to the system voltage, cables with appropriate rated voltage should be selected to ensure safe transmission. High insulation resistance can reduce signal loss and improve transmission efficiency. In an environment with large electromagnetic interference, shielded cables should be selected to reduce interference. When purchasing, it is necessary to select the appropriate number of cable cores and cross-sectional area, such as selecting the appropriate number of cores according to the complexity of the control system and the number of signals. In addition, choose the appropriate cross-sectional area according to the transmission distance and current size to ensure that the cable will not overheat. When purchasing, you should also pay attention to the material and manufacturing process of the control cable. Copper conductors have excellent conductivity and are our common choice. Insulating materials generally include polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), etc., which are common insulating materials, each of which has its own characteristics. The choice of sheath material is also very important because it will affect the wear resistance, weather resistance and fire resistance of the cable.

Choosing the right control cable is a meticulous and important task. By comprehensively considering the use environment, electrical performance, number of cores and cross-sectional area, material and manufacturing process, cost and brand, as well as industry standards and specifications, you will be able to select the control cable that best meets your needs and provide a strong guarantee for the stable operation of the system.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable