Why do people choose copper core cables?

In the field of power transmission, choosing the right cable material is crucial. There are copper core and aluminum core wires in society. Although aluminum core cables have certain advantages in price and weight, copper core cables are more often chosen in the electrical field. Below, we will explore the limitations of aluminum core cables and explain the key reasons why copper core cables are superior.

1. Difference in conductivity

The conductivity of aluminum is much lower than that of copper. Although aluminum core cables are lighter and cheaper, due to their poor conductivity, aluminum core cables with larger cross-sectional areas are required to transmit the same current. This not only increases the size and installation difficulty of the cable, but also leads to higher energy loss and reduces the efficiency of power transmission.

2. Inadequate mechanical properties

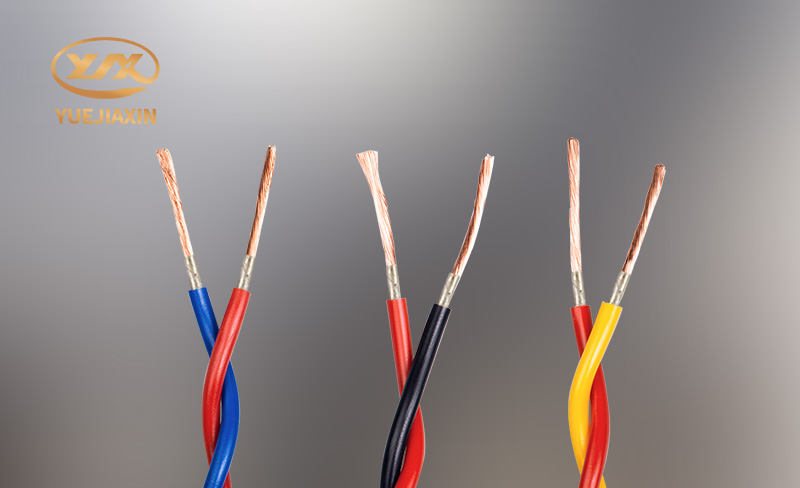

The mechanical strength of aluminum is lower than that of copper. Especially in the case of multiple bending and twisting, aluminum core cables are more prone to breakage and fatigue problems. In practical applications, this means that the reliability of aluminum core cables is far less than that of copper core cables when facing complex installation environments and long-term use.

3. Contact problems

Aluminum is easily oxidized in the air to form a layer of aluminum oxide film, which has electrical insulation properties and may increase contact resistance, thereby causing poor contact problems. Copper is relatively stable and not easy to oxidize, so it can maintain good conductivity at joints and connections, reducing the failure rate.

4. Thermal expansion coefficient

The thermal expansion coefficient of aluminum is larger than that of copper. In an environment with large temperature changes, aluminum core cables are more likely to deform, resulting in loose joints, affecting the reliability and safety of the cable. This is particularly evident in high temperature or cold environments, increasing the frequency of maintenance and replacement.

Although aluminum core cables have advantages in cost and weight, their deficiencies in conductivity, mechanical strength, oxidation resistance and thermal expansion coefficient make them difficult to be used as power cables. For power transmission that requires high reliability and high efficiency, copper core cables are still a more ideal choice.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

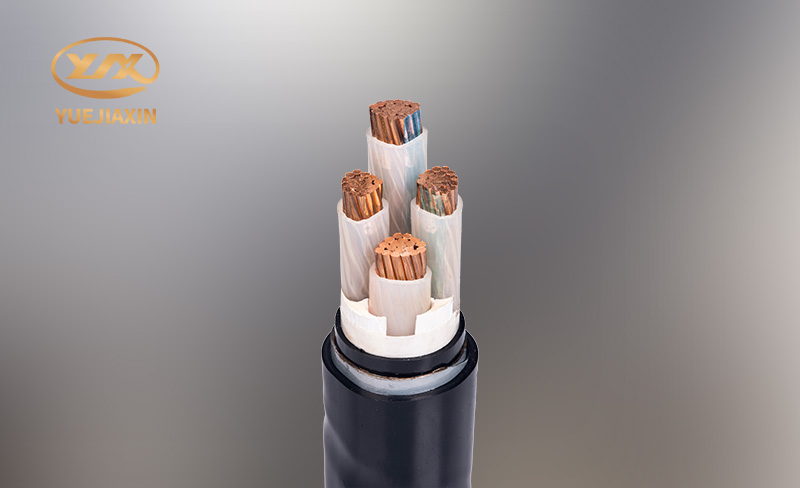

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable