When purchasing flame retardant cables, you should pay attention to the following issues:

With the rapid development of the national economy and the electric power industry, the demand for wires and cables has increased sharply, but the number of fires caused by non-flame-retardant cables has also increased. In order to reduce the occurrence of fires caused by cable burning, various types of flame-retardant cables It came into being at the historic moment, but some purchasers do not know much about flame-retardant cables, resulting in the inability to correctly select cables when purchasing. Let’s take a look at what issues you need to pay attention to when choosing flame-retardant cables.

1.Consider the grade of flame retardant cables

When selecting flame retardant cables, consider the grade of the cable. The flame retardant grades are divided into four categories ABCD according to different materials. ZA means flame retardant class A; ZB means flame retardant class B. Class A flame retardant conditions are the most stringent, so the flame retardant grade ranking is A>B>C. The higher the flame retardant grade, the better the flame retardant performance of the wire and cable. Different places require different flame retardant levels of cables. For example, places with densely populated areas such as high-rise buildings, shopping malls, schools, etc. have higher requirements for the selection of flame retardant levels of cables.

2.Consider the laying environment of flame-retardant cables

When selecting flame-retardant cables, you also need to consider the cable laying environment. For example, in underground cable tunnels and deep water areas, flame retardant cables with water resistance, corrosion resistance and waterproof properties should be selected. In the petrochemical and chemical industries, flame-retardant cables with corrosion resistance should be selected.

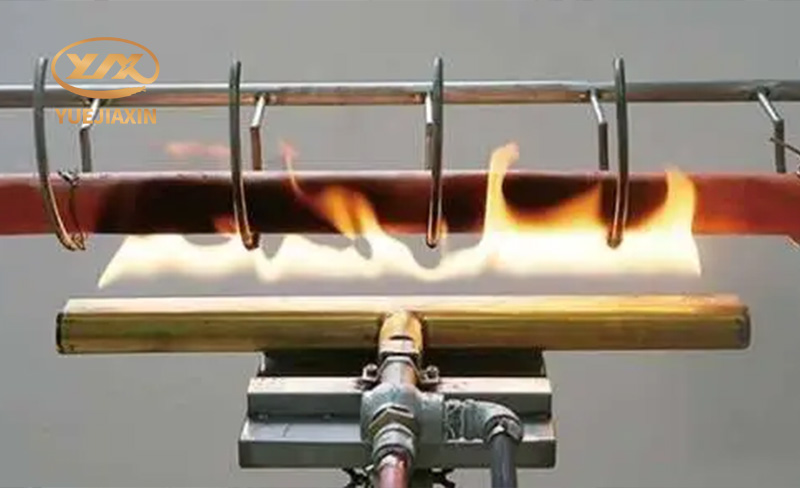

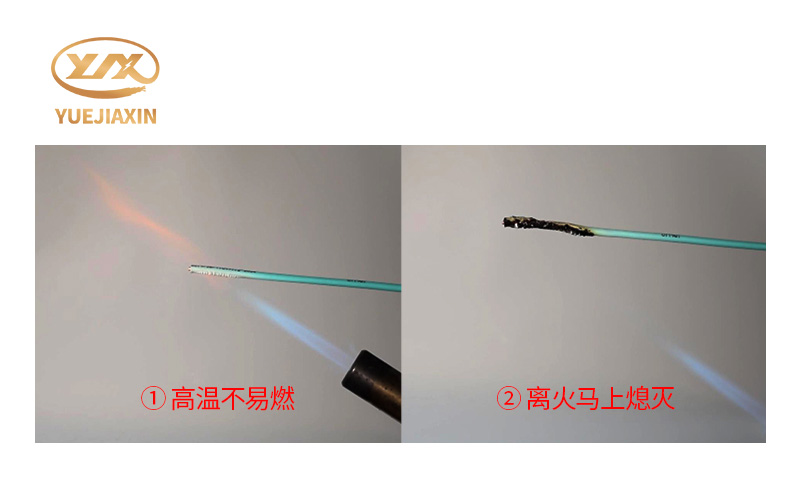

3.Consider the reliability of flame retardant cables

When choosing flame-retardant cables, make sure they comply with national and industry standards and have high reliability. When choosing a regular manufacturer, carefully check the quality and appearance of the cable to ensure that the cable is not damaged or broken.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable