What is power cable

The use of power cables has a history of more than 100 years. In 1879, American inventor T.A. Edison wrapped jute around a copper rod and threaded it into an iron pipe, and then filled it with an asphalt mixture to make a cable. He laid this cable in New York and pioneered underground power transmission. The following year, the Englishman Callender invented the asphalt-impregnated paper insulated power cable. In 1889, the British S.Z. Ferranti laid a 10 kV oil-impregnated paper insulated cable between London and Detford. In 1908, the UK built a 20 kV cable network. Power cables are being used more and more widely. In 1911, Germany laid a 60 kV high-voltage cable, which started the development of high-voltage cables. In 1913, the German M. Horchstedt developed a component-phase shielded cable, which improved the electric field distribution inside the cable and eliminated the tangential stress on the insulating surface, which became a milestone in the development of power cables. In 1952, Sweden laid 380 kV EHV cables in the northern power plant, realizing the application of EHV cables. By the 1980s, UHV power cables of 1100 kV and 1200 kV had been made.

Ⅰ、main classification

According to the voltage level, it can be divided into medium and low voltage power cables (35kV and below), high voltage cables (above 110kV), ultra-high voltage cables (275-800kV) and UHV cables (1000kV and above). In addition, it can also be divided into AC cables and DC cables according to the current system.

Classification by voltage class

1. Low-voltage cables: suitable for fixed laying on transmission and distribution lines with AC 50Hz and rated voltage of 3kv and below for power transmission.

2. Medium and low voltage cables: (generally refers to 35KV and below): PVC insulated cables, polyethylene insulated cables, XLPE insulated cables, etc.

3. High-voltage cables: (generally 110KV and above): polyethylene cables and XLPE insulated cables, etc.

4. Ultra-high voltage cable: (275~800KV).

5. UHV cable: (1000KV and above).

Classified by insulating material

1. Oil-impregnated paper insulated power cable is a power cable with oil-impregnated paper as insulation. Its application history is the longest. It is safe and reliable, has a long service life and is inexpensive. The main disadvantage is that the laying is limited by the drop. Since the development of non-drip paper-impregnated insulation, the problem of drop limit has been solved, allowing oil-impregnated paper-insulated cables to continue to be widely used.

2. Plastic insulated power cables Power cables whose insulation layer is extruded plastic. Commonly used plastics are polyvinyl chloride, polyethylene, and cross-linked polyethylene. The plastic cable has the advantages of simple structure, convenient manufacturing and processing, light weight, convenient laying and installation, and is not limited by the laying drop. Therefore, it is widely used as medium and low voltage cables, and has a tendency to replace sticky impregnated oil-paper cables. Its biggest disadvantage is the presence of dendritic breakdown, which limits its use at higher voltages.

3. Rubber insulated power cable The insulating layer is made of rubber plus various compounding agents. After fully mixing, it is extruded and wrapped on the conductive wire core, and is formed by heating and vulcanization. It is soft and elastic, suitable for frequent movement and small bending radius.

The rubber materials commonly used for insulation include natural rubber-styrene-butadiene rubber mixture, ethylene propylene rubber, butyl rubber, etc.

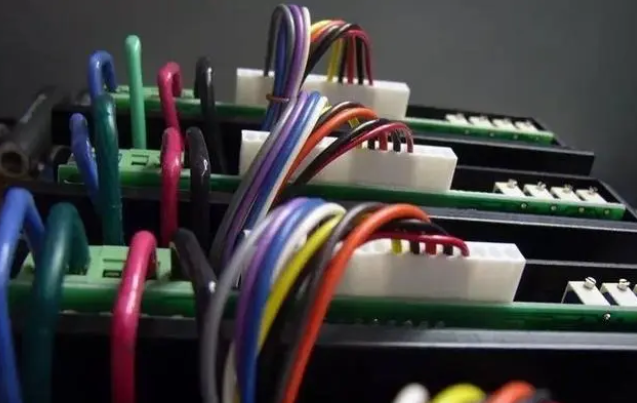

Ⅱ、Basic Structure

The basic structure of a power cable consists of four parts: the core (conductor), the insulating layer, the shielding layer and the protective layer.

The wire core is the conductive part of the power cable, which is used to transmit electrical energy and is the main part of the power cable.

Insulation: The insulating layer is to electrically isolate the core from the ground and the cores of different phases from each other to ensure the transmission of electric energy, and is an indispensable part of the power cable structure.

Shielding layer: Power cables of 15KV and above generally have a conductor shielding layer and an insulating shielding layer.

Protective layer: The role of the protective layer is to protect the power cable from the intrusion of external impurities and moisture, and to prevent the power cable from being directly damaged by external forces.

Ⅲ. Main advantages

1 occupies less space. Generally buried in soil or laid indoors, in trenches and tunnels, the insulation distance between lines is small, no poles and towers are required, and it occupies less land and basically does not occupy space on the ground.

2 High reliability. Less affected by climatic conditions and surrounding environment, stable transmission performance and high reliability.

3 It has more favorable conditions for the development of ultra-high voltage and large capacity, such as low temperature, superconducting power cable, etc.

4 The distributed capacitance is larger.

5. Less maintenance work.

6 The possibility of electric shock is small.

Yuejiaxin produces cables:PVC cable, XLPE cable,electric cable,power cable, LV cable