The difference between photovoltaic cables and ordinary cables

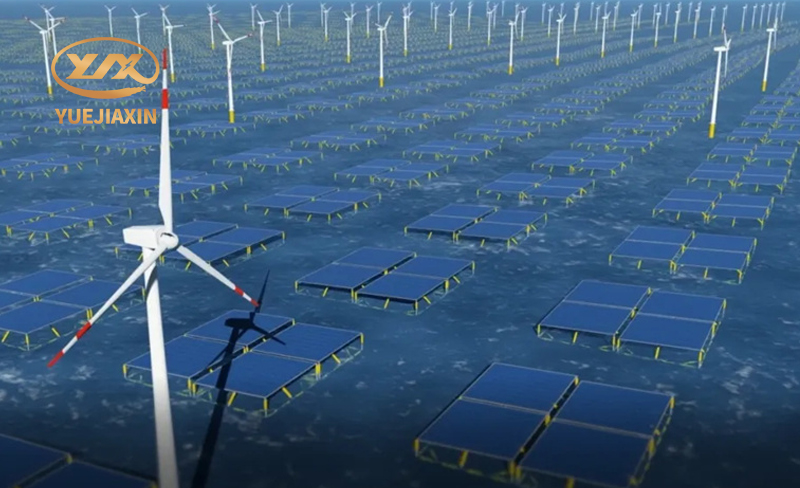

Photovoltaic cables, as the name implies, are photovoltaic cables. They are mainly used in photovoltaic power stations. They are resistant to high temperatures, cold, oil, acid and alkali, UV, flame retardant, environmentally friendly, and have a long service life. They are mainly used in harsh climate conditions. Common models include PV1-F and H1Z2Z2-K. Photovoltaic cables are often exposed to sunlight, and solar energy systems are often used in harsh environmental conditions, such as high temperatures and UV radiation.

In power transmission and renewable energy systems, there are significant differences in structure and performance between photovoltaic cables and ordinary cables. Here are the main differences between them:

1. Purpose and environment

The main purpose of photovoltaic cables is to connect solar panels and solar inverters to transmit the electrical energy generated by the photovoltaic power generation system to power stations or electrical energy storage devices. Photovoltaic cables need to adapt to extreme environments such as outdoors, high temperatures, and ultraviolet radiation, because solar panels are usually installed outdoors and exposed to the natural environment. Ordinary cables are used for general power transmission, including construction, industry, homes and other fields. For different application scenarios, ordinary cables may need to consider properties such as fire resistance, abrasion resistance, and chemical corrosion resistance.

2. Conductor material

Photovoltaic cables usually use copper or aluminum as the conductor material. Copper conductors have good electrical conductivity but are relatively heavy. Aluminum conductors are lightweight and less expensive, but are slightly less conductive than copper. The conductor materials of ordinary cables are diverse and can be copper, aluminum or copper-aluminum alloy, depending on the application field and requirements of the cable.

3. Insulation materials

The insulation materials of photovoltaic cables usually use high-performance materials, such as cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR) to improve insulation performance. The choice of insulation materials for ordinary cables varies depending on the purpose, and can be polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), rubber, etc.

4. Sheath materials

The sheath of photovoltaic cables usually uses UV-resistant and high-temperature resistant materials, such as cross-linked polyethylene (XLPE) or polyvinyl chloride (PVC). The choice of ordinary cable sheath materials may use different types of materials depending on the purpose, such as polyvinyl chloride (PVC), low smoke zero halogen (LSZH), etc.

5. Flame retardant performance

In order to improve safety, some photovoltaic cables use special materials with good flame retardant properties, such as flame retardant cross-linked polyethylene (FR-XLPE). The flame retardant performance requirements of ordinary cables may vary depending on the application field.

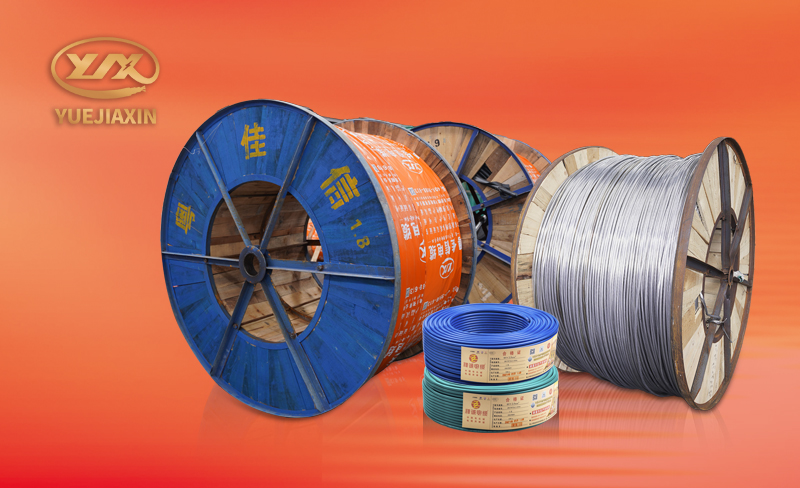

Foshan Yuejiaxin Wire & Cable Co., Ltd. was established in 1999. Since its establishment, it has been committed to the production of wire and cable products. The company's products mainly include thousands of varieties such as power cables, control cables, cables for electrical equipment, mineral cables, and home decoration cables. The products are deeply favored and welcomed by consumers.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable