PVC Cable and Wire Manufacturing Process

The process involved in making PVC wires and cables is fairly simple and cost-effective because it’s been refined over a long period of time. This is why PVC wires and cables are cheaper compared to other cables and wires.

The material PVC used in PVC wires and cables goes through a process called polymerization. This is where PVC is easily softened by heating making it highly versatile and giving all the flexible properties which PVC wire and PVC cable are well known for.

This process also makes PVC wires and cables lightweight and reduces ‘dielectric losses’ and internal stress in electrical applications – making it easily usable within any appliances or any industry. However, the strength, longevity, and durability of cables and wires remain unchanged by this process.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

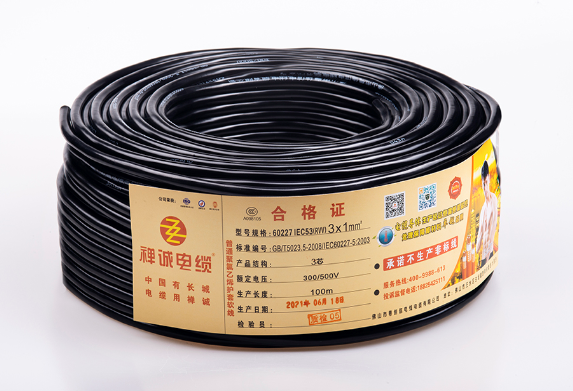

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable