How to identify the quality of cables?

Wires and cables are closely related to our daily lives. Although small, they have great responsibilities. Moreover, the quality of wires and cables is directly related to circuit safety. Many fires and electric shock accidents are caused by poor quality wires and cables. So how to distinguish the quality of wires and cables? Here are some suggestions on how to choose wires and cables.

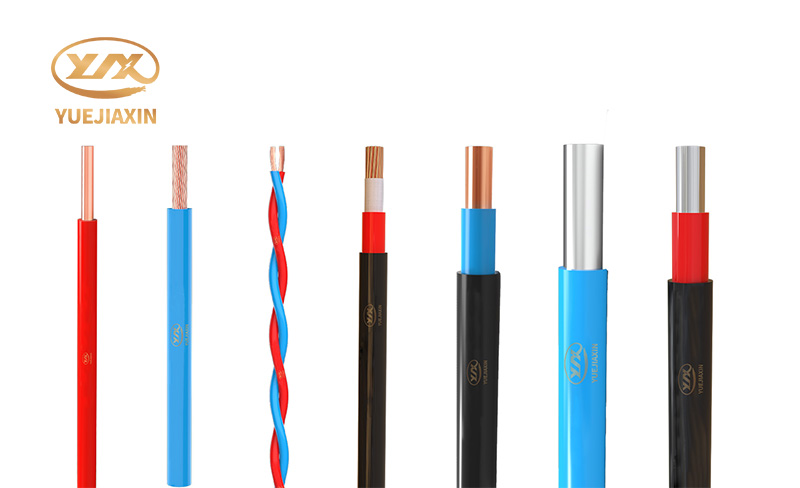

First, look at the appearance of the product. Qualified and high-quality wire products will have the following contents marked on the outer packaging, such as the certificate of conformity, the manufacturer's information and address, the inspector, the production date, the trademark, the specifications, etc.

Secondly, check the conductor material of the wire. Generally, copper cores are used for wires and cables. However, the purity of copper is different, and its conductivity is also good or bad. The best is generally purple-red, slightly reddish, with fewer impurities and soft texture. If the conductor is whitish and lighter in color, it proves that there are more impurities in the copper; if the conductor is black and has a strong sense of hierarchy, this kind of copper is commonly known as "iron copper", and there are great hidden dangers in use.

Then, look at the position of the wire core conductor. A good cable conductor must be located in the center of the insulation layer. The non-centering is caused by the eccentricity caused by failure to meet the process requirements. When using low-power electrical appliances, it can meet the performance requirements. Once high power is used, it will cause the current to heat up and the thinner side is likely to be broken down by the current.

If conditions permit, we can also conduct tests. For example, if we measure weight, good quality wires are generally within the specified weight range. For example, the commonly used plastic insulated single-strand copper core wire with a cross-sectional area of 1.5 weighs 1.8 to 1.9 kg per 100 m. Poor quality wires are not heavy enough, either the length is not enough or there are too many impurities in the copper core of the wire. To measure the crease, take a wire and bend it repeatedly by hand, fold it in half several times. Those that feel soft, have good fatigue resistance, have a high elasticity of plastic or rubber, and have no cracks on the wire insulation are excellent products. If the insulation layer turns white, cracks, or the conductor breaks, it proves that there is a problem with the quality of the wire. To measure flame retardancy, use a lighter to ignite the wire. A qualified wire will produce blue smoke. After the insulation layer is ignited, take away the lighter and it should extinguish itself within five seconds. Otherwise, it is a wire that does not meet the fire protection standards. This kind of wire is easy to cause accidents such as leakage and fire.Foshan Yuejiaxin Wire and Cable Co., Ltd. has more than 20 years of production experience, and its products are deeply loved by consumers.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable