How to choose photovoltaic cables?

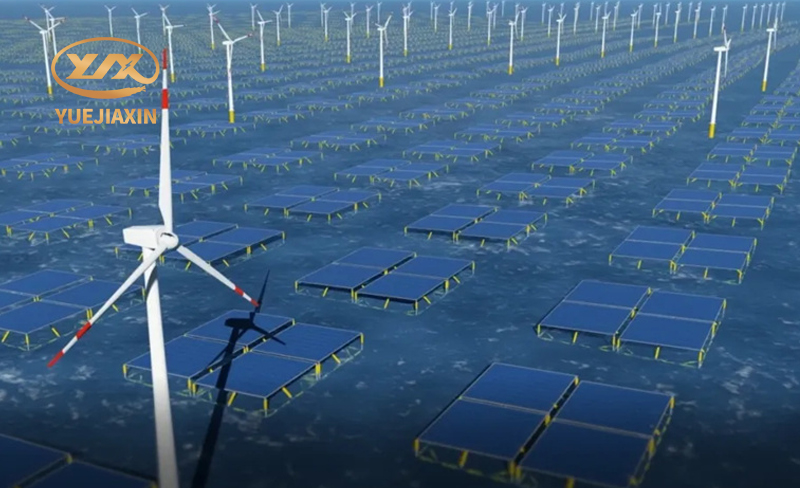

In recent years, photovoltaic industry technology has been developing faster and faster. In terms of system design, the use of high-power components and reasonable reserved space can reduce the initial investment cost and kilowatt-hour cost of the system. So how should we design and select to reduce costs?

What are the options for photovoltaic power station cables?

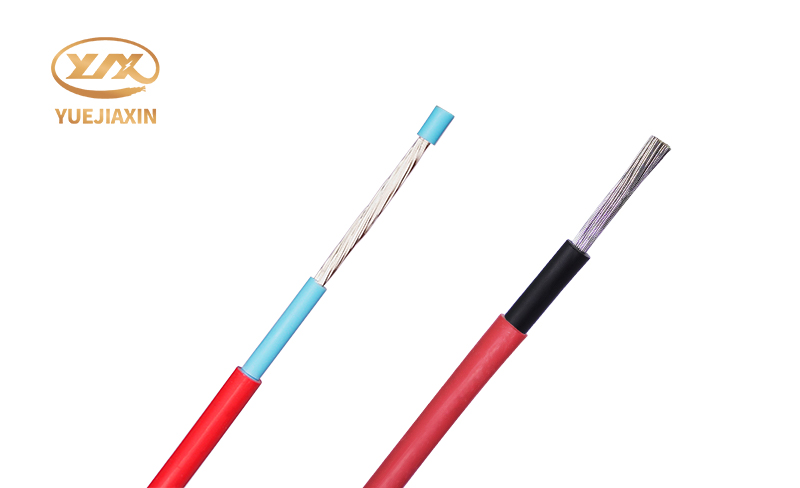

1. Selection of DC cables

Select according to the current of the photovoltaic module. It is usually recommended to use photovoltaic-specific DC cables. These cables are made of materials that are resistant to ultraviolet rays and ozone, and can withstand severe temperature changes and chemical erosion. They are suitable for long-term use outdoors. The cross-sectional area of photovoltaic cables is usually between 1.5mm2 and 35mm2, with 4mm2 cables being the most commonly used. With the increase of photovoltaic module current and stand-alone inverter power, the increase of cable length also makes the application of 6mm2 DC cable more common. The loss of DC cables should generally not exceed 2%, which is an important criterion for selecting cables. For example, if the DC voltage is 600V, a 2% voltage drop loss is 12V. For component currents exceeding 13A, it is recommended to use a 6 mm2 DC cable and keep the farthest end of the component within 150 meters of the inverter.

2. Selection of AC cable.

AC cable selection should be determined based on the maximum current of the inverter. In photovoltaic power plants, the configuration of components and inverters is usually not in a 1:1 ratio, and there may be a certain amount of overprovisioning. Therefore, AC cable selection should be based on the maximum current of the inverter.

3. Selection of other connecting cables.

For connecting cables between solar cell modules and modules, connecting cables between batteries and AC loads, the rated current of the cables generally selected is 1.25 times the continuous operating current of each cable. For the connecting cables between solar cell arrays and the connecting cables between batteries (groups) and inverters, the rated current of the cables generally selected is 1.5 times the continuous operating current of each cable.

What are the requirements for selecting cables for photovoltaic systems?

1. High temperature resistance.

Because photovoltaic panels are exposed to sunlight for a long time and have high surface temperatures, the cables need to be able to withstand high temperature environments without deformation or damage.

2. Pressure resistance.

The voltage generated by the photovoltaic system is relatively high, and the cables must be able to withstand this voltage to ensure safe operation of the system.

3. Weather resistance.

Photovoltaic systems are usually installed outdoors, and the cables must be able to withstand harsh natural environments, such as ultraviolet rays, wind and rain, etc., and maintain good electrical performance.

4. Aging resistance and corrosion resistance.

Since photovoltaic systems need to operate for a long time, the cables should not age during long-term use and can resist corrosion in humid environments to maintain appearance and electrical performance.

In summary, single-core cables and multi-core cables each have their own advantages and applicable scenarios, and the selection should be based on specific application requirements.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable