Cable manufacturers teach you how to identify qualified wires and cables

During the renovation process, choosing qualified wires and cables is the key to ensuring the safety of household electricity. There are many types of wires and cables on the market, and the quality varies. Therefore, as consumers, we need to master some methods to identify the qualification of wires and cables to avoid purchasing unqualified cable products. The following are the tips for identifying qualified wires and cables summarized by wire and cable manufacturers.

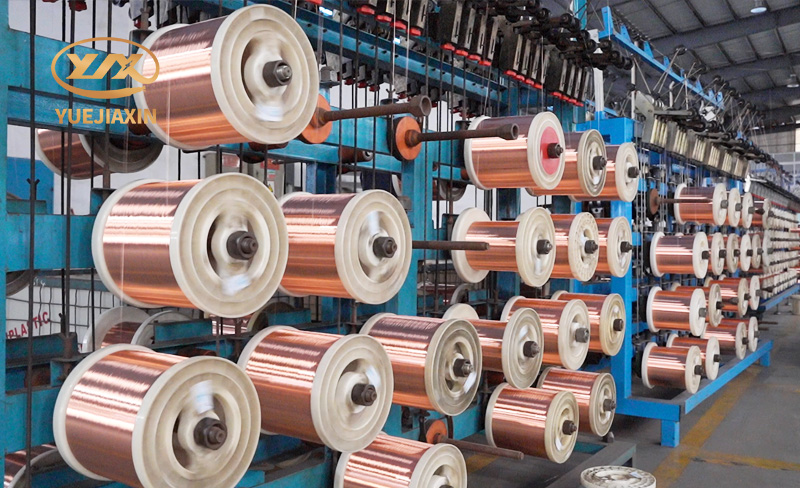

1. Identification of copper quality. Qualified copper core wires should have a purple-red, shiny, and uniform brightness. The copper core of inferior wires is darker, dull, and even black or gray. This is because inferior copper materials contain more impurities, which affect the conductivity and service life; secondly, high-quality copper core wires are soft to the touch and have a certain degree of flexibility. Inferior wires have many impurities in copper materials, feel harder, and are easy to break, which affects the convenience of construction and use.

2. Identification of manufacturers. The outer packaging of qualified wires and cables should have clear manufacturer names, addresses, trademarks, and related certification marks. Regular manufacturers usually print detailed production information and quality assurance marks on their products. Counterfeit and shoddy wires are often "three-no products" with unclear marks.

3. Identification of prices. The prices of qualified wires and cables are relatively stable. Consumers can judge the authenticity of the products by comparing the prices of similar products on the market. Counterfeit and shoddy wires usually attract consumers at low prices due to their low production costs. Too low prices often mean poor quality and potential safety hazards.

When purchasing wires and cables, be careful not to buy low-priced products for cheapness. Vendors often use the pretext of "cheap and good quality" to sell fake and shoddy wires at low prices, deceiving consumers. Quality and safety should be the first factor, and products with reasonable prices and guaranteed quality should be selected.

When purchasing wires and cables, be sure to conduct a comprehensive identification through copper quality, manufacturer and price. High-quality wires and cables not only help improve the quality of decoration, but also ensure the safety of household electricity use and avoid safety hazards caused by wire quality problems.

Since its establishment in 1999, Foshan Yuejiaxin Wire and Cable Co., Ltd. has insisted on strictly controlling product quality for more than 20 years, strictly controlling every production process and carefully checking every test to ensure that the produced wires and cables meet national standards and International Electrotechnical Commission standards, providing safer protection for consumers.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable