What is the difference between solar cables and ordinary cables?

In our daily life and various production activities, cables play a vital role. They are a key component of power transmission.

From the perspective of economic life electricity consumption, whether it is the operation of various electrical appliances in the home or the electricity consumption of office equipment in the office, it is inseparable from the use of cables to transmit electricity. It is like the "micro-vessels" of the human body, ensuring the supply of electricity so that our lives can be carried out normally and orderly. For example, in industrial production, if large-scale machinery and equipment, production lines, etc. in the factory want to operate, cables are responsible for transmitting electricity from sources such as power stations, injecting power into the entire industrial production activities, and promoting the continuous production.

In the field of transportation, the operation of rail transportation tools such as subways and high-speed railways relies on cables to transmit electricity to ensure the normal operation of trains and the electricity demand of various facilities in the station; and in construction projects, from the electrical equipment in the construction process to the power distribution inside the building after completion, cables are indispensable.

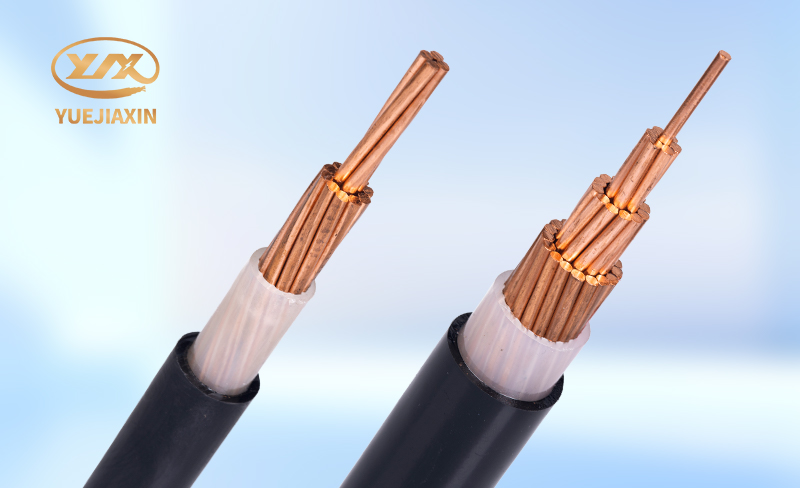

What are the differences between solar cables and ordinary cables? As a cable specially designed for photovoltaic power generation systems, the composition of each part of solar cables has unique material selection and corresponding advantages. In terms of conductors, copper conductors or tinned copper conductors are usually used. Copper itself has excellent conductivity, which can ensure that the energy loss of current is minimized during transmission. The anti-oxidation performance of copper conductors after tinning is enhanced, which can better meet the needs of long-term operation of photovoltaic systems. For the insulation part, most of them use radiation cross-linked polyolefin insulation materials. After the radiation cross-linking process, the molecular structure of polyolefin changes, making it have excellent high temperature resistance, UV resistance and chemical corrosion resistance. It can effectively ensure the stable transmission of current, prevent current leakage and reduce energy loss under harsh outdoor environmental conditions, such as long-term exposure to sunlight and temperature changes. In terms of sheath, radiation cross-linked polyolefin sheath is often used. It cooperates with the insulation material as the outer protective barrier of the cable to resist the influence of external mechanical damage, moisture, chemical erosion and other factors, further enhancing the overall durability and stability of the cable. These special material combinations jointly determine that solar cables can meet the performance requirements of photovoltaic systems to continuously, efficiently and safely transmit DC power in complex and harsh outdoor environments.

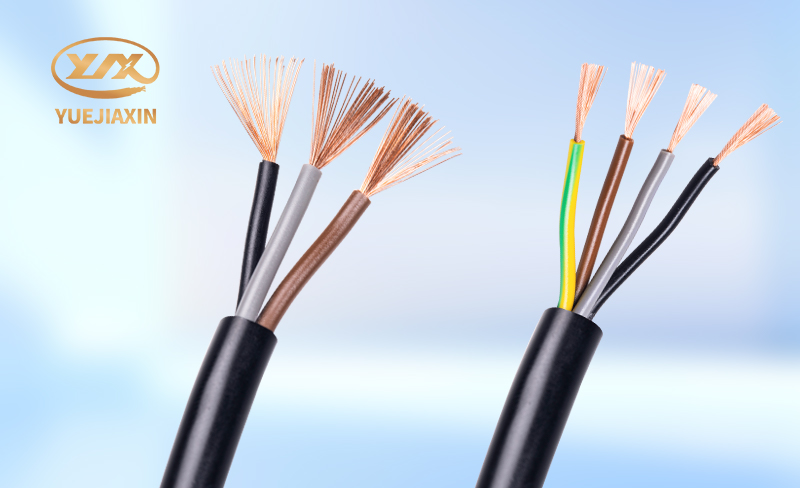

The composition of ordinary cables is more diverse in the selection of conductors, insulation and sheaths to adapt to different usage scenarios and needs. The conductor can also be made of materials such as copper or aluminum. Copper conductors have good conductivity, while aluminum conductors have certain cost advantages. The selection is based on the specific usage occasion and the comprehensive consideration of cost and conductivity. In terms of insulation, common insulation materials are PVC or XLPE. Ordinary cables with PVC insulation have relatively convenient processes and low costs. They are widely used in some low-voltage cables that do not require particularly high performance such as temperature resistance; while ordinary cables with XLPE insulation have better electrical and mechanical properties and are suitable for a variety of medium and low voltage power transmission scenarios. In terms of sheath materials, PVC sheath is a more commonly used one. It can provide certain protection for the internal structure of the cable to prevent external physical damage and erosion by moisture, chemicals, etc., but compared with the sheath of solar cables, it is slightly weaker in terms of weather resistance and other aspects.

In general, ordinary cables are significantly different from solar cables in terms of basic composition. Their material selection focuses more on meeting the universal requirements under different use environments, unlike solar cables, which focus on special material adaptation for the special harsh environment of outdoor solar systems.

In terms of performance, what are the differences between solar cables and ordinary cables? First of all, in terms of temperature resistance, solar cables have excellent high temperature and cold resistance. It can adapt to a wide temperature range, is suitable for various harsh climatic conditions, and can transmit electricity for solar power generation in a long-term and stable manner. Ordinary cables have a relatively narrow temperature resistance range. For example, the long-term allowable operating temperature of common household wires is mostly around 70°C. Even if some ordinary cables with special formulas or high-performance insulation materials have improved high temperature resistance, their overall performance is significantly limited in extreme temperature environments compared to solar cables. For example, in a high-temperature industrial production environment, if the temperature is far beyond the tolerance range of ordinary cables, problems such as softening of the insulation layer and accelerated aging may occur, affecting the normal use and life of the cable. In a cold environment, it is also easy to become hard and brittle, reduce flexibility, and even cause damage to the internal conductor, which cannot guarantee stable power transmission. Secondly, in terms of environmental resistance, solar cables have excellent environmental resistance, and have many advantages such as UV resistance, oil resistance, acid, alkali and salt resistance, and anti-aging. Since most photovoltaic systems are outdoors, solar cables are often exposed to the sun for a long time, and must withstand complex outdoor environments such as wind, rain, and dust erosion. However, with its excellent environmental resistance, it can still ensure safe and reliable power transmission. The sheath of ordinary cables often has poor UV resistance, and long-term outdoor use is prone to aging of the outer sheath. Once the outer sheath ages, it is difficult to provide good protection for the internal insulation layer and conductor, which in turn affects the service life of the cable. Moreover, when aging is severe, the insulation layer may be damaged, leading to hidden dangers such as short circuits and fire alarms, and may even cause dangerous injuries to people around. There are also differences in flame retardancy and environmental protection. Solar cables are made of halogen-free and flame-retardant materials, which is a major highlight. When burning, it does not produce toxic smoke and corrosive gases. It is environmentally friendly and does not endanger the health and safety of people around it. It has good environmental performance. In addition, solar cables are recyclable and reusable, which is in line with the current concept of green development and sustainable development. For example, when building photovoltaic power stations in areas with high environmental protection requirements, solar cables can be used without worrying about the generation of a large amount of harmful smoke polluting the environment when a fire occurs, and can achieve the dual effects of clean energy production and environmental protection. Ordinary cables are relatively conventional in terms of flame retardancy and environmental protection performance. Many ordinary cables may produce thick smoke and toxic and harmful gases when burning, which poses a potential threat to the environment and human health, and are not as convenient and environmentally friendly as solar cables in terms of recyclability. Compared with solar cables, the shortcomings of ordinary cables in these aspects are highlighted. In some occasions with strict environmental protection and safety requirements, the applicability of ordinary cables will be greatly reduced.

Through the detailed introduction above, we know that solar cables and ordinary cables are obviously different in many aspects. Therefore, the rational selection of cables according to actual conditions is of great significance to ensure the stable operation of the power system. If the usage scenario is an outdoor photovoltaic-related project, solar cables can ensure stable transmission of electric energy by virtue of their ability to adapt to harsh environments; if it is an ordinary indoor power usage scenario, ordinary cables can meet the corresponding needs and achieve a better balance in terms of cost and other aspects. Only by choosing the right cables can the power transmission system operate efficiently and safely.